The principle of the technology is the lack of backbone in the constructed buildings. Arched shell buildings - Self-supporting and light metal construction. It does not require massive deep foundations and load-bearing skeletons (columns, trusses, beams). The foundation for the arch frameless designs can be belt or screw piles.

The principle of the technology is the lack of backbone in the constructed buildings. Arched shell buildings - Self-supporting and light metal construction. It does not require massive deep foundations and load-bearing skeletons (columns, trusses, beams). The foundation for the arch frameless designs can be belt or screw piles.

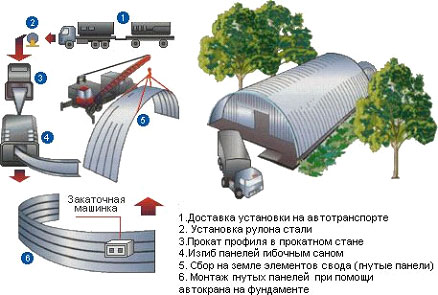

Cold-arched arched elements are made of rolled galvanized steel directly on the construction site section bending machine. With canning machine arcs together in section 5 pieces sealed seams. This technology creates a complete watertightness seaming structure (principle tin) and eliminates the need for fasteners used in frame technology. The sections are then mounted onto the prepared foundation and rolled together.

The process of manufacturing and assembly is not difficult with a special forming machine.

It consists of several stages.

|

Step 1. Development of the site and preparation of the ground (basement) On the whole process for the hangar area on the floor of 1 000 sq.m. It takes 20-25 days (cold performance). |

|

|

Installers BRiS-Stroymontazh guarantee the fulfillment of all the work with the highest quality in the shortest possible time.