The history of the hangar construction

The technology of prefabricated construction is relatively recent. The first hangars were facilities that were designed exclusively for the parking of various aerial vehicles, as well as for maintenance and repair. The term "shed" was directly associated with aircraft and airships. We build the first wooden hangar. But the development of aviation on the threshold of the First World War gave impetus to the construction of hangars. In Germany, there were first sheds made of steel. Subsequently, the experience of using metal structures in the construction of hangars picked up by engineers in other countries.

The technology of prefabricated construction is relatively recent. The first hangars were facilities that were designed exclusively for the parking of various aerial vehicles, as well as for maintenance and repair. The term "shed" was directly associated with aircraft and airships. We build the first wooden hangar. But the development of aviation on the threshold of the First World War gave impetus to the construction of hangars. In Germany, there were first sheds made of steel. Subsequently, the experience of using metal structures in the construction of hangars picked up by engineers in other countries.

After the Second World War, the greater part of the Eurasian continent engaged in restoration of the people from the ruins. Growing economy in all sectors of the economy. Gradually sheds are used not only for aircraft, and large appliances. They began to be used also as industrial warehouses, production facilities, vegetable and grain silos, areas for cattle. The most advanced and creative design engineers offer a lot of projects using the principles of frameless hangar technologies in the construction of office buildings, construction of cultural and leisure destination.

Hangar construction technology in their development process was divided into two parts: frame and frameless.

Hangar construction technology in their development process was divided into two parts: frame and frameless.

During the construction of frame sheds used classical principle of the installation of steel structures, and these stacked sheets made of metal or plastic. Application of load-bearing columns requires a fairly high cost of materials due to their weight.

With the construction of frameless hangars as materials used rolled galvanized steel thickness of 1.0 - 1.5 mm. In order to achieve the strength of a sheet made of arches her pre-shirred on a special equipment. Then prepared arched elements are connected by seaming machines and mounted on a prepared foundation. Features of this technology is the lack of heavy load-bearing elements, thus achieving a significant reduction in price the cost of the entire building.

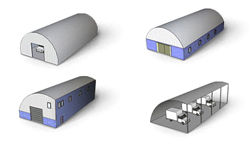

Sheds can be classified by their appearance in several groups:

- Hangar arch type

- Hangar tent type

- Hangar with vertical walls

- Hangar polygonal type

Hangar arched frame

The basis of this hangar is carrying arched element from flat welded trusses interconnected runs. In the finished frame is laid cover. The most commonly used materials - steel sheet. Because of the need for bending the coating material is impossible to use the sandwich panel. For fastening to the supporting arches runs using bolted connections. Perhaps insulation hangar second coating layer of the multilayer structure with the creation and application of the internal insulated material.

The basis of this hangar is carrying arched element from flat welded trusses interconnected runs. In the finished frame is laid cover. The most commonly used materials - steel sheet. Because of the need for bending the coating material is impossible to use the sandwich panel. For fastening to the supporting arches runs using bolted connections. Perhaps insulation hangar second coating layer of the multilayer structure with the creation and application of the internal insulated material.

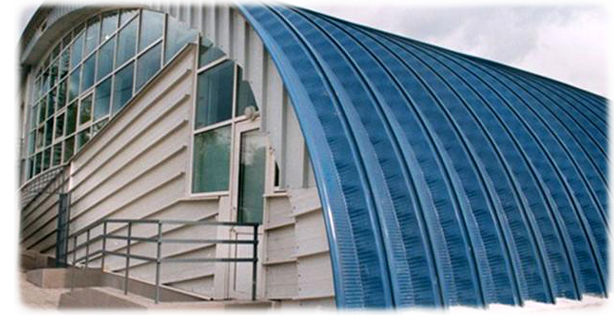

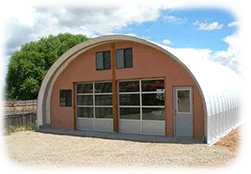

Arched hangars frameless

A radical departure from his brother at the frame of this type is the lack of hangars pillars. Arch elements made of galvanized sheet by shaping it, are fully self-supporting, and its technical characteristics in no way inferior frame technology. As with brick embodiment, a hanger may be manufactured in a warm embodiment. The package may include skylights, gates both end and side.

A radical departure from his brother at the frame of this type is the lack of hangars pillars. Arch elements made of galvanized sheet by shaping it, are fully self-supporting, and its technical characteristics in no way inferior frame technology. As with brick embodiment, a hanger may be manufactured in a warm embodiment. The package may include skylights, gates both end and side.

The highlight of this technology -  is the ability to apply different forms of a building under construction, combined direct and semi-circular design, which makes greater use of its functional purpose of such buildings. This arrangement may be used not only for the whole structure, but also as a roof of the finished building.

is the ability to apply different forms of a building under construction, combined direct and semi-circular design, which makes greater use of its functional purpose of such buildings. This arrangement may be used not only for the whole structure, but also as a roof of the finished building.

Hangar tent

Hangar tent - a metal structurewith a gable roof and walls, tilted into the room at a certain angle and narrowed upwards. The framework consists of a tent hangar hinged on the foundation tent arches of constant radius arranged with a certain pitch. Arches frame raskrepleny laterally with metal struts and girders. Total hardness is provided by a system of vertical and horizontal, and the wind relationships.

Hangar tent - a metal structurewith a gable roof and walls, tilted into the room at a certain angle and narrowed upwards. The framework consists of a tent hangar hinged on the foundation tent arches of constant radius arranged with a certain pitch. Arches frame raskrepleny laterally with metal struts and girders. Total hardness is provided by a system of vertical and horizontal, and the wind relationships.

The coating material tent hangars can be very different, depending on the operating conditions: high quality PVC tent, made of anodized aluminum, galvanized. The coating material  is attached to the construction of self-tapping screws.

is attached to the construction of self-tapping screws.

As with previous versions of hangars, tent can be insulated by the device multi-layer coating or a coating of sandwich panels.

Scope tent hangars: as agricultural complexes, such as piggeries, barns, and granaries ovosche- and the like, as well as industrial and production bases and buildings, warehouses and storage bases, garages for equipment and so on. d.

Hangar with vertical walls

Hangars with vertical

Hangars with vertical  walls are a design of plane frames located steps from three to six meters, fixed rigidly to the foundation or hinged. Frames frame skrepyayutsya interconnected metal struts and girders galvanized.

walls are a design of plane frames located steps from three to six meters, fixed rigidly to the foundation or hinged. Frames frame skrepyayutsya interconnected metal struts and girders galvanized.

The frame of the hangar can be crane tracks for the equipment capacity up to 10 tons. The buildings (hangars) from the vertical walls can be carried out one - or multi-span. The width of the span - up to 24 meters. The length of the building is not limited. Such a building can be built taller than one floor. The total  hardness of the hangar through a system of vertical and horizontal linkages. The main frame material - channels, I-beams, pipes and specialized areas. Wall coverings can serve galvanized profiled sheet or sandwich panel (in the insulated version).

hardness of the hangar through a system of vertical and horizontal linkages. The main frame material - channels, I-beams, pipes and specialized areas. Wall coverings can serve galvanized profiled sheet or sandwich panel (in the insulated version).

Obshivka walls and the roof can also be made of galvanized trapezoidal sheet with a polymer coating.

This design is by far the most common form of construction hangar facilities thanks

its versatility, ease of installation and aesthetic appearance.

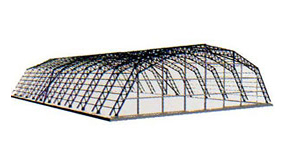

Hangar polygonal type

Polygonal design allows you to build hangars spans a width of 50 m. And a height of 15 m. Hangar is very similar to the tent, but different arches and guardrail. Arch frame consists of lattice trusses or I-beams. Arches installed every 3-6 meters of monolithic pile or pier foundation.

Polygonal design allows you to build hangars spans a width of 50 m. And a height of 15 m. Hangar is very similar to the tent, but different arches and guardrail. Arch frame consists of lattice trusses or I-beams. Arches installed every 3-6 meters of monolithic pile or pier foundation.

Polygonal hangars appearance reminiscent of tents, but there are significant differences. Prefab hangar polygonal arches are I-beams or trusses, inscribed in an ellipse, not a circle, as in the arch or tent structures. The height of the shed will normally be equal to one third of its width.

As a polygonal cladding of the hangar can be used in sandwich panels or shaped sheet. For the "cold" performance sheds most common cladding made of galvanized sheet, "warm" polygonal structures often built of prefabricated panels with pre-applied insulation.

The package may include polygonal hangar different number of doors and gates as the end and side. Without much effort into the wall plane can be installed plastic windows.